Economic Advantages of the Industrial Air Compressor

Interested in learning about industrial air compressor sustainability? Sustainability is a hot topic of conversation lately. In fact, the Compressed Air & Gas Institute notes three of the top benefits for compressed air: energy, environment, and cost. When most people think of industrial air compressors, sustainability is not what first comes to mind. However the […]

3C Loves Our Veterans

3C is proud to be a Veteran owned and operated company. We are honored to be a place of employment for other retired military men and women alike. In honor of Veterans Day, we are featuring a few of our Veterans on the 3C team. Meet Chase Stokley From 2013 – 2017, Chase served in […]

State of the Industry: Air Compressors 2021

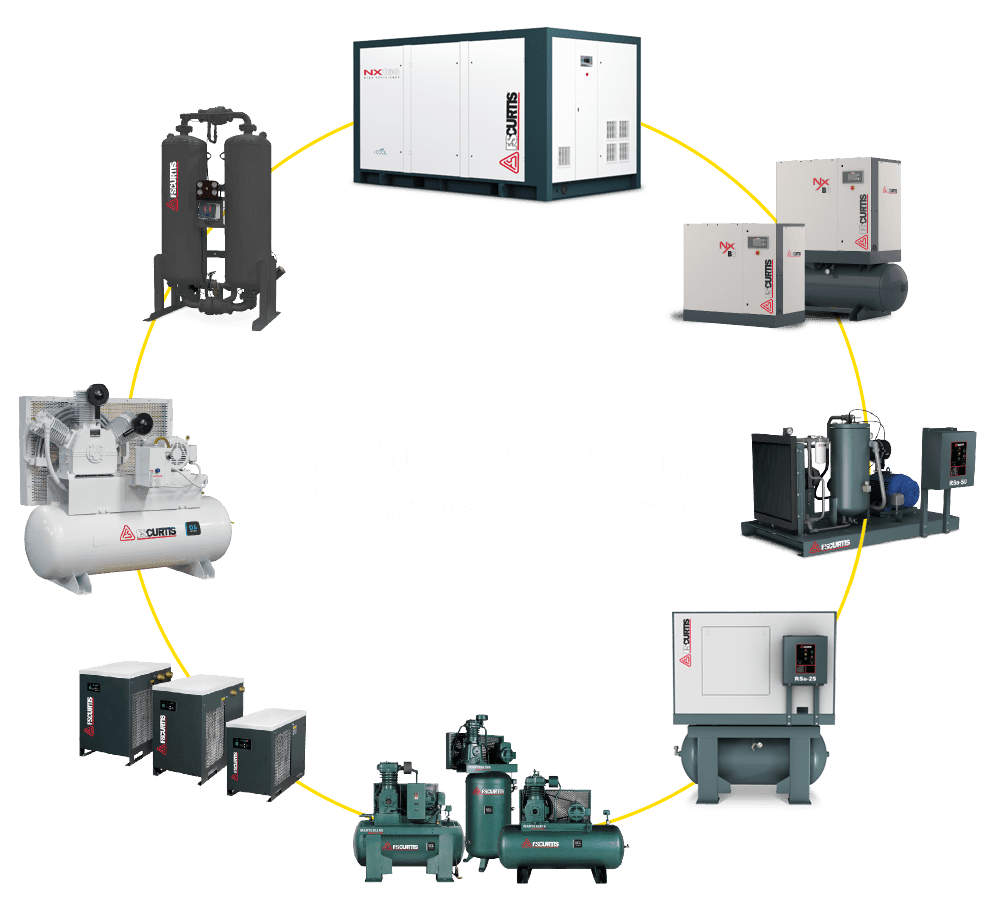

3C Industrial is in the business of air compressors. Anything and everything you need to know about air compressors, we have an answer. We want to take a quick look at the state of the industry for air compressors. We’re looking at what the market is doing now, where it’s going and how 3C fits […]

A Quick History of the Air Compressor

Air compressors are used in a variety of settings for multiple purposes. Today, compressors are used in agricultural, power engines, medical, mining, oil & gas and manufacturing industries. The air compressor helps in an array of ways, but back in the day they weren’t as versatile. They required a lot more manual activity than they […]

Air Compressor 101: Everything You Need to Know

Air compressors can seem complicated at first! If you’re thinking about owning– or even renting– one, it’s a good idea to do some research beforehand to familiarize yourself with the machine. Here are some terms every air compressor owner should be familiar with. Terms for you to Know Cubic feet per minute (CFM): The volume […]

3C is Honored to Employ U.S. Military Veterans

3C is Honored to Employ U.S. Military Veterans 3C is a veteran owned and operated company! We are honored to be a place of employment for other retired military men and women! Here we feature every one of them as a ‘Thank you for your service!’ Learn about each of these amazing veterans below! Hi, […]

A COVID-19 Message From 3C

Hello Community, 3C has been closely monitoring the news and is saddened by the spread of the coronavirus throughout the world. We would first like to send our deepest condolences to all those affected by the virus. However, at 3C, we are in no state of panic. We are calm and ready to assist any […]

A Letter From 3C’s CEO

A Letter From 3C’s CEO Hello! My name is Doug Francis. I have been the President of 3C Industrial for nearly 8 years. I have dedicated my entire career to servicing others. My journey to serve others began in 2002 when I joined the United States Navy. While there, I took orders to serve onboard […]