Do I Need a Desiccant or Refrigerated Air Dryer?

Air dryers are essential for the majority of compressed air applications. By nature, air compressors produce a lot of water. The atmosphere of air is compressed and the air gets very hot. When the air temperature decreases, the moisture that was in those atmospheres turns from a gas to a liquid. While some of the […]

New or Used Air Compressor: Which One Is Best?

When looking for an air compressor, you can choose between buying new or used. This decision comes after deciding the specific type of compressor you need. There are plenty of pros and cons for either option and diverse factors to your choice. We’re here to help you outline the advantages and disadvantages of a new […]

Does Your Compressor Need an Upgrade?

Are you doing corrective maintenance more and more every quarter? Are you shouting when chatting near your compressor? Do these scenarios sound familiar? These are all telltale signs that it may be time to upgrade your air compressor. Are you exceeding repairs? A good rule of thumb most of our customers follow on repairs is […]

Summer Maintenance Tips

Summertime is officially here in Texas. The summer brings long, hot and humid days, all of which can take a toll on your air compressor. Skyrocketing temperatures combined with condensation can strain your equipment’s performance unless you’re prepared. Here are some summer maintenance tips that we at 3C have put together to help you with […]

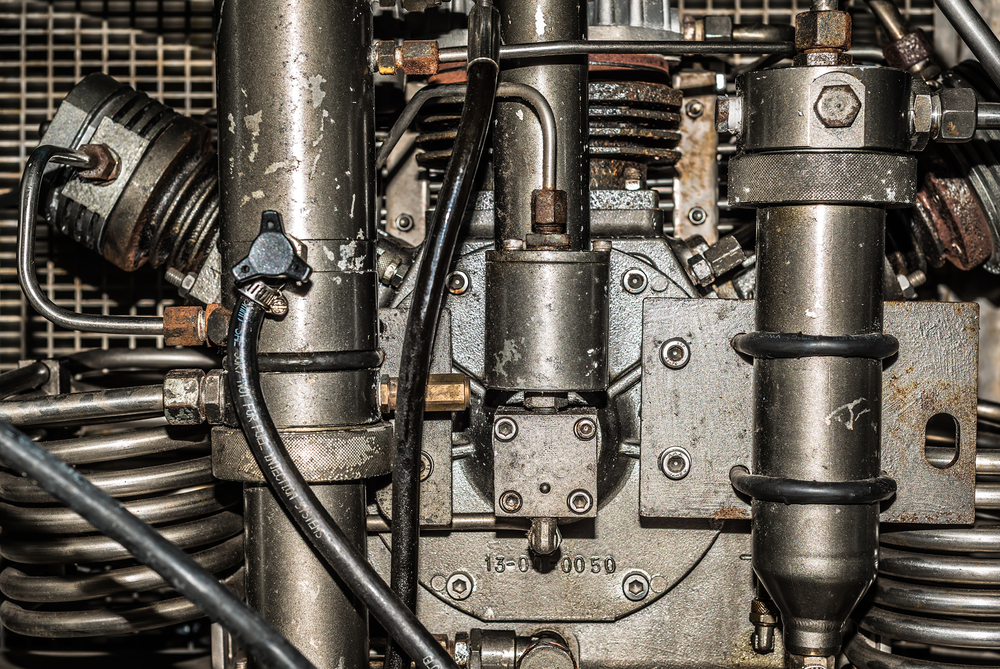

A Quick History of the Air Compressor

Air compressors are used in a variety of settings for multiple purposes. Today, compressors are used in agricultural, power engines, medical, mining, oil & gas and manufacturing industries. The air compressor helps in an array of ways, but back in the day they weren’t as versatile. They required a lot more manual activity than they […]